AI Summary

MIT engineers have developed artificial muscle tissue that can flex in multiple directions simultaneously, allowing for greater range of motion and flexibility. They achieved this using a 3D-printing technique that stamps microscopic grooves into soft hydrogel, seeding real muscle cells to grow fibers in specific patterns. This breakthrough has potential applications in soft robotics, medicine, and beyond, including biodegradable robots, advanced prosthetics, and regenerative medicine.

Imagine a future where robots move with the fluidity of living creatures, squeezing through tight spaces with ease and swimming through water with fish-like grace. This vision is coming closer to reality thanks to groundbreaking research from

MIT, where engineers have developed artificial muscle tissue capable of contracting in multiple directions simultaneously.

Nature's Blueprint

Our natural muscles are marvels of biological engineering. They don't just pull in straight lines – they form complex patterns allowing for an incredible range of motion and flexibility. When we move, countless muscle fibers twitch and pull in perfect coordination. Some muscles align in one direction, while others form intricate patterns that enable parts of our body to move in multiple ways.

Scientists have long been inspired by this complexity, working to create artificial muscles that could power a new generation of "biohybrid" robots – machines powered by soft, artificially grown muscle fibers rather than rigid mechanical actuators. However, until this breakthrough, researchers had only been able to fabricate artificial muscle that pulls in one direction, severely limiting any robot's range of motion.

The Breakthrough

MIT engineers, led by

Ritu Raman, the Eugene Bell Career Development Professor of Tissue Engineering in MIT's Department of Mechanical Engineering, have now developed a method to grow artificial muscle tissue that twitches and flexes in multiple coordinated directions.

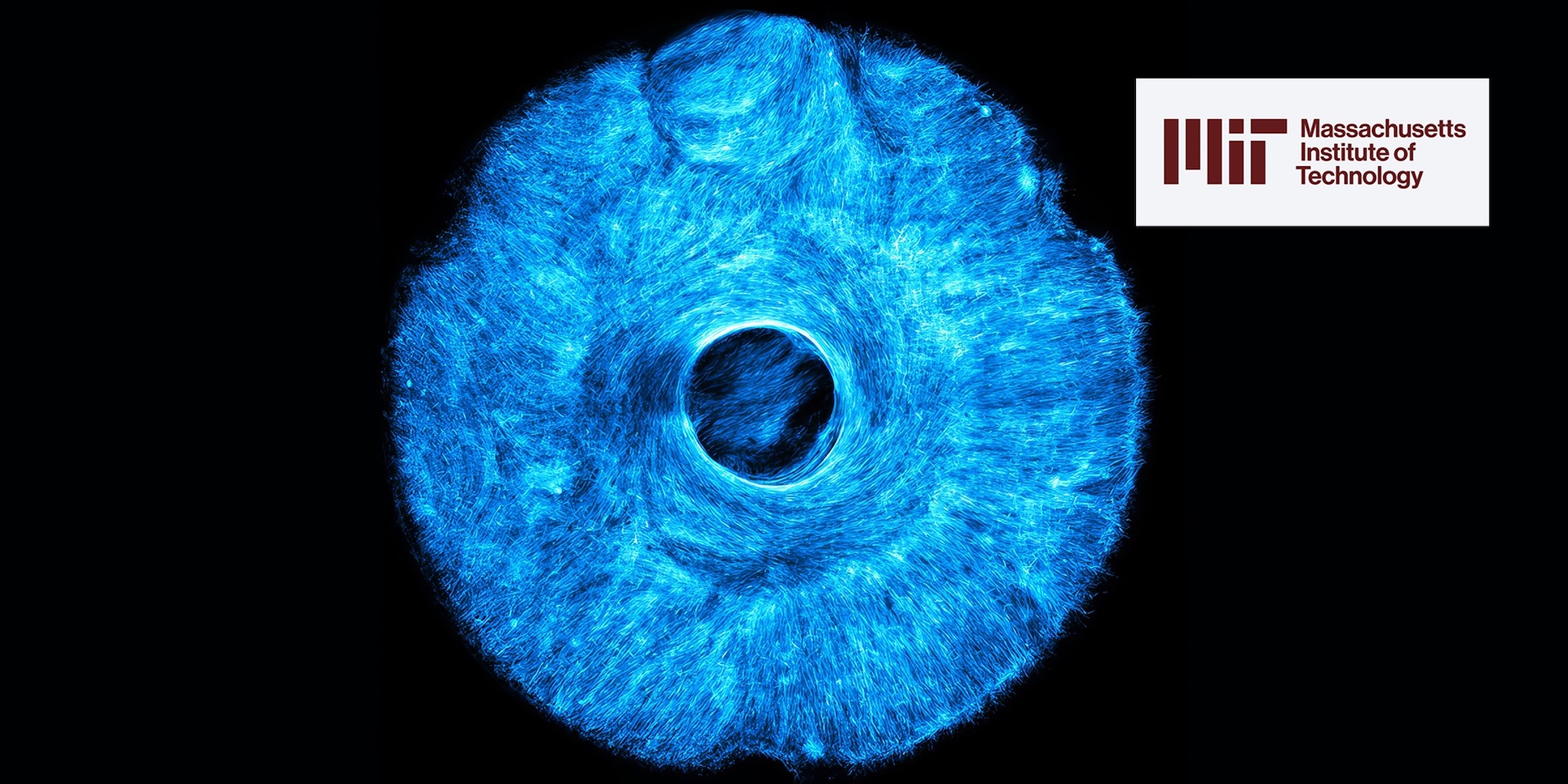

As a demonstration of this capability, they grew an artificial, muscle-powered structure modeled after the human iris – a structure that pulls both concentrically and radially to dilate and constrict the pupil. This represents what researchers believe is "the first skeletal muscle-powered robot that generates force in more than one direction."

The Stamping Technique

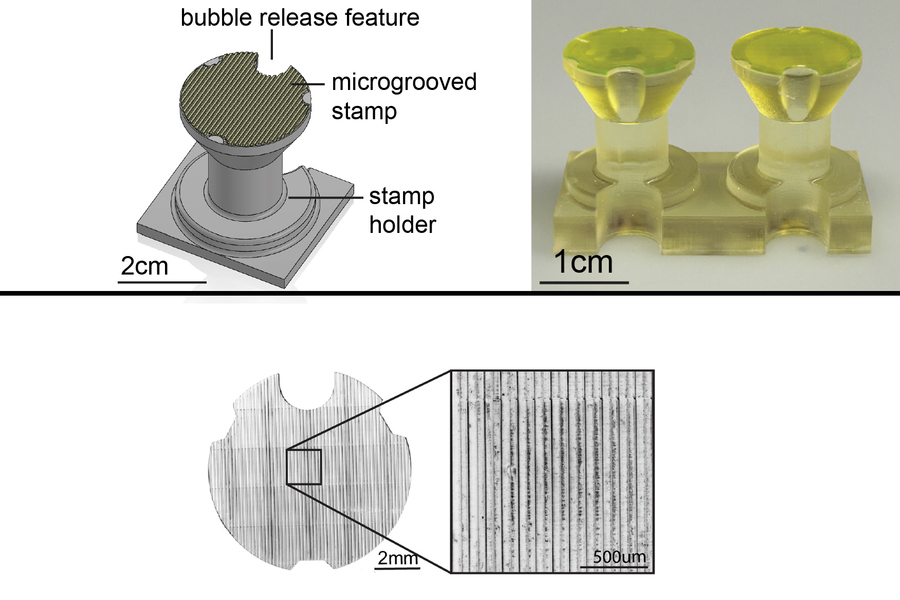

The key innovation behind this breakthrough is surprisingly simple in concept, though complex in execution: a stamping technique. Here's how it works:

- First, the team 3D-printed a small, handheld stamp patterned with microscopic grooves

- Each groove is as small as a single cell

- They pressed the stamp into a soft hydrogel

- Before pressing, they coated the stamp with proteins to ensure it imprinted smoothly without tearing the fragile gel

They seeded the resulting grooves with real muscle cells - The cells followed these grooves as they grew, forming fibers in specific patterns

- When stimulated, the muscle contracted in multiple directions, following the fibers' orientation

"The idea is simple. But how do you make a stamp with features as small as a single cell? And how do you stamp something that's super soft? This gel is much softer than Jell-O, and it's something that's really hard to cast, because it could tear really easily," Raman explains.

The Artificial Iris in Action

For their demonstration, the researchers patterned their artificial muscle after the human iris – the ring of muscle surrounding the pupil. In our eyes, this muscle comprises an inner circle of fibers arranged concentrically (in a circular pattern) and an outer circle of fibers that stretch radially (like sun rays). This complex architecture allows the iris to constrict or dilate the pupil.

The team engineered the cells to respond to light pulses. Within just one day, the cells fell into the microscopic grooves and began to fuse into fibers, following the iris-like patterns and eventually growing into a complete muscle structure with an architecture similar to a real iris.

When stimulated with light pulses, the artificial iris contracted in multiple directions – just like the muscles in our eyes that adjust pupil size. Although the real human iris uses smooth muscle tissue (involuntary muscle), the team demonstrated using skeletal muscle cells (voluntary muscle), showing the versatility of their stamping technique.

Beyond Muscles: The Future of Soft Robotics

What makes this breakthrough even more exciting is its potential applications beyond muscle tissue. The team says their stamping method isn't limited to muscle cells – it could potentially be used to grow complex patterns of other biological tissues, such as neurons and heart cells, that look and act like their natural counterparts.

"We want to make tissues that replicate the architectural complexity of real tissues," Raman says. "To do that, you really need this kind of precision in your fabrication."

This new capability opens up exciting possibilities for the field of soft robotics. Traditional robots use rigid components that limit their ability to navigate through tight or complex spaces. Biohybrid robots powered by artificial muscles could:

- Navigate underwater with fish-like flexibility

- Squeeze through tight spaces where traditional machines cannot go

- Be completely biodegradable and sustainable

- Operate with greater energy efficiency than conventional robots

"Instead of using rigid actuators that are typical in underwater robots, if we can use soft biological robots, we can navigate and be much more energy-efficient, while also being completely biodegradable and sustainable," Raman explains. "That's what we hope to build toward."

Medical Applications

Beyond robotics, this technology has promising applications in medicine. Raman's lab aims to engineer biological materials that mimic the sensing, activity, and responsiveness of real tissues in the body. This could lead to:

- Artificial tissue that can restore function to people with neuromuscular injuries

- Advanced prosthetics with more natural movement capabilities

- New approaches to tissue engineering for regenerative medicine

What's Next

The research team published their open-access results in the journal

Biomaterials Science on March 17, 2025.

Going forward, Raman and her colleagues plan to apply the stamping method to other cell types, as well as explore different muscle architectures and activation methods. The goal is to create biohybrid robots capable of performing useful work in real-world applications.

As this technology continues to develop, we may soon see a new generation of robots that blur the line between mechanical and biological systems. It's a vision of robotics that takes inspiration from nature's blueprints, potentially revolutionizing how we think about machines and their capabilities.

Recent Posts